Smart

maintenance

Optimise your machinery

Service comes first in everything we do. With 8 locations spread through the country, 300 professional employees and 100 service vans, we are there for you day and night.

Facta has 13 specialists who are fully committed to optimising your machinery.

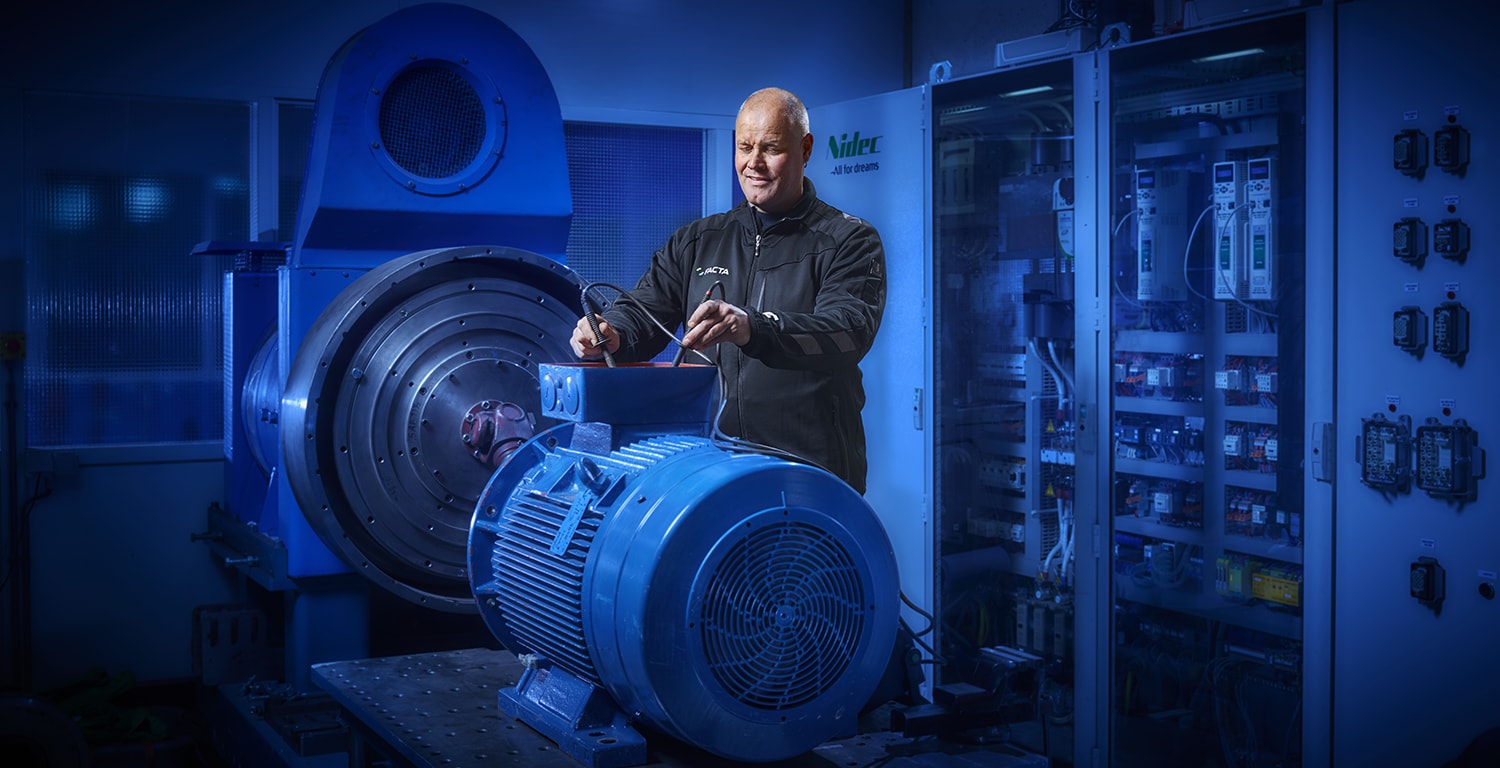

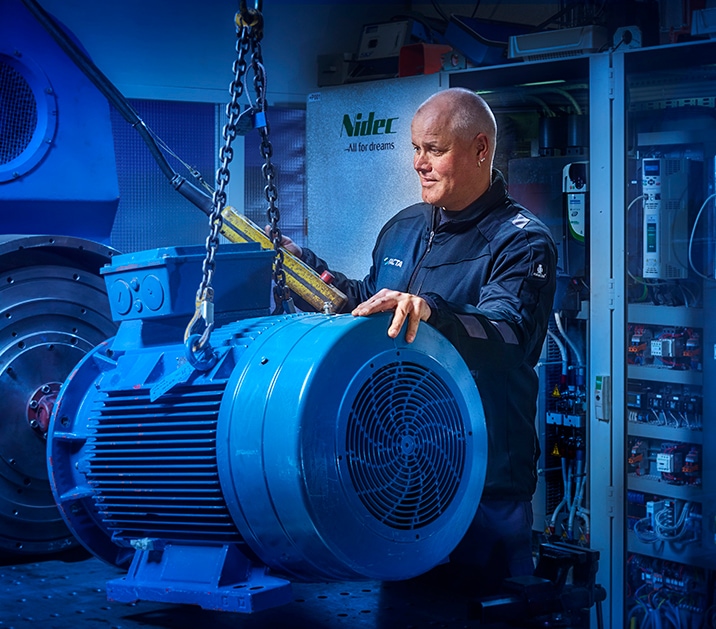

When something stops spinning, the whole chain can be affected. At Facta, we understand that like no other. You can always contact us for repairs and overhauls, but for us, maintenance means much more than that. Facta is at the cutting edge of Smart Maintenance. We will help you avoid downtime, improve your processes and increase your reliability.

The possibilities are enormous, to the extent that you may find yourself paralysed. Because if everything seems possible… where do you start? However, the fact that everything is possible does not mean that you have to do everything or do everything at once. We can start laying the foundations for smart maintenance together and see where we go from there!

Do you have a problem with your rotating equipment right now? You can reach us day and night – we’ll get started right away.

Opt for planned maintenance for greater certainty.

Determine the condition of your machinery by means of inspections or troubleshooting. Depending on the outcome, we will plan maintenance together.

Actively collecting relevant measurement data to monitor the condition of your machinery. The aim is to prevent problems by identifying deviations.

Based on algorithms and machine learning, determine when statistically speaking maintenance needs to be performed on your rotating equipment.

We know exactly what your business is all about. If you have a problem now, you want a solution right away. Not tomorrow. That’s why we’re always nearby. 24 hours a day. 7 days a week. Service comes first in everything we do. In order to be able to act quickly, we always have large numbers of electric motors, pumps and generators in stock. Never want to miss out again? Just let us manage your stock!

”

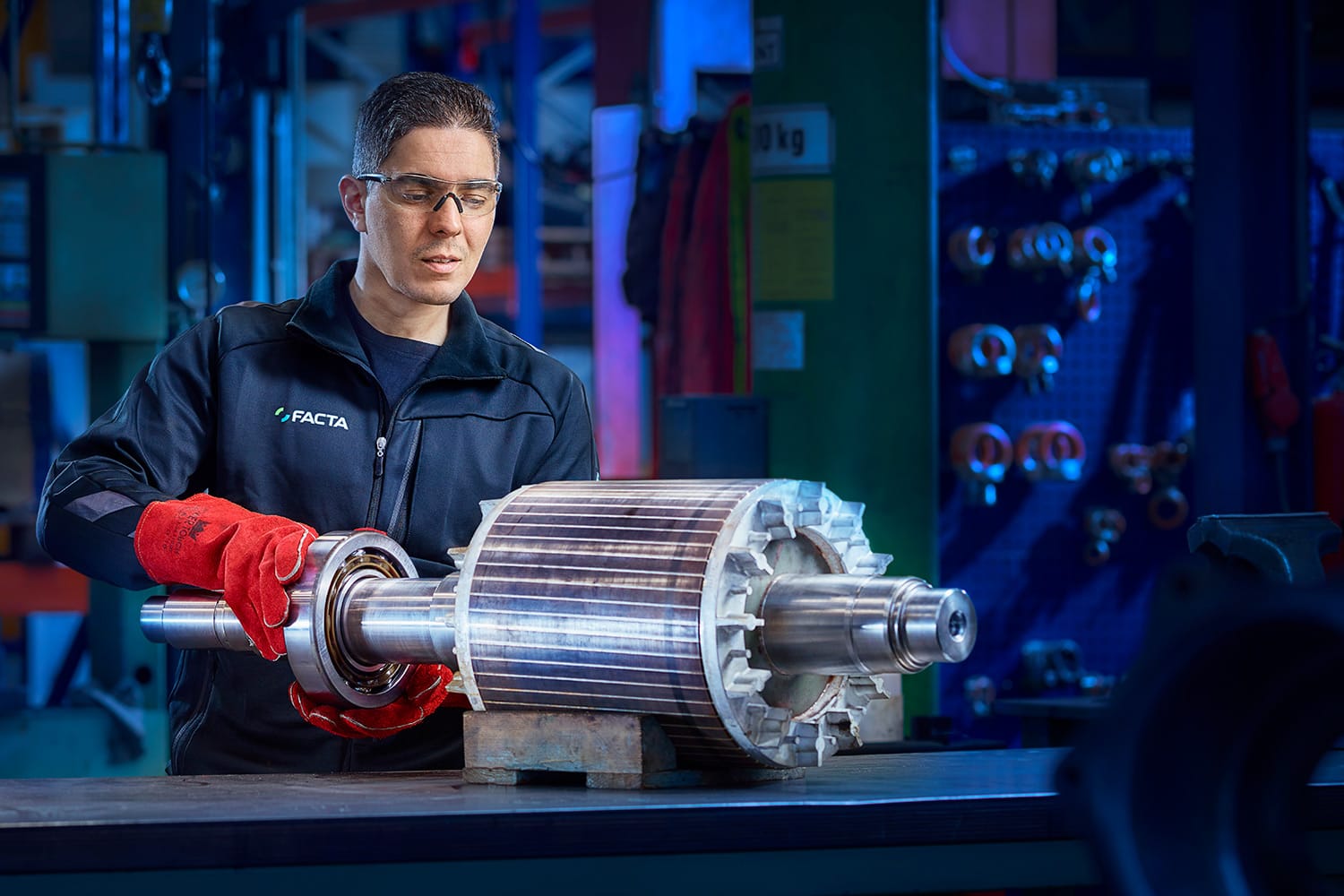

We know that you want to avoid unforeseen disruptions to your production process at all costs. Structural maintenance is a great way to prevent costly disruptions. If you’ve planned a short production stop, we’ll schedule our people right away. Have you planned a slightly longer stop? Overhauling 25 pumps or electric motors in two weeks’ time is a piece of cake for us. We approach our work with the down-to-earth enthusiasm you can expect from real go-getters.

We will carry out visual inspections or condition assessments to determine the condition of your machinery. Sometimes, we’ll only have to replace a seal. Sometimes a motor will have to be swapped out. In other cases, the problem may not be visible right away. That’s when we start troubleshooting. Using our advanced equipment, we’ll exclude potential causes step by step. We might even find an unexpected cause. Naturally, we’ll solve whatever problem we encounter. That’s what we do.

”

Proactive maintenance is a key principle of the digital factory of the future. Imagine periodic vibration monitoring, online monitoring and infrared thermography, to name but a few techniques and technologies. Everything depends on collecting the right data. And interpreting them, of course. Facta specialists know their way around this proactive approach to maintenance. We monitor, analyse and advise, with the aim of increasing the uptime of your machinery. You can get started with proactive maintenance at several different levels. Data is worth its weight in gold. But what can you do with data? And which data do you need to achieve your objectives? Facta’s specialists will meet with you first to discuss and explore the best possible system for your situation, laying the foundation for predictive maintenance.

Predictive maintenance requires a good database that stores all the necessary data. Using algorithms and machine learning, the system can then tell you that your drive system is currently A-OKAY, for example, but that statistics predict that you will start experiencing problems between now and a certain time. For such a system to work properly, it’s important that we lay a sound foundation first. We’d love to sit down with you and talk about making your production process future-proof.

Craftsmanship, quality and safety are paramount at Facta, as is evident from our certifications and accreditations.

Would you like to know which approach best suits your situation? Please feel free to contact us. Call +31 (0)88 6000 200 or e-mail us.

Uitgeest

Westerwerf 11

1911 JA Uitgeest

T: +3188 6000 200

uitgeest@facta.nl

Nederweert

Pannenweg 208

6031 RK Nederweert

T: +31495 634 141

nederweert@facta.nl

Spijkenisse

Röntgenweg 6

3208 KG Spijkenisse

T: +3188 6000 300

spijkenisse@facta.nl

Zevenhuizen

Nijverheidscentrum 36

2761 JP Zevenhuizen

T: +3188 7384 702

zevenhuizen@facta.nl

Appingedam

Holepolder 1

9902 SM Appingedam

T: +3188 7384 720

appingedam@facta.nl

Dronrijp

De Alde Mar 11

9035 VP Dronrijp

T: +31517 231 232

friesland@facta.nl

Staphorst

Roelof Brinkstraat 3

7951 DW Staphorst

T: +3188 7384 700

staphorst@facta.nl

© 2020 Facta

Privacy & Policy Statement

Terms & Conditions